AccelStor's All-Flash Array Helps the Intelligent Transformation of the World's "Lighthouse Factories"

-

![2023121509522756]() Customer Profile

Customer ProfileWith a daily processing task of 8,000 customer orders, where 80% entail customized needs of fewer than five units, this company has achieved an impressive 45% increase in labor productivity. Often referred to as a "Lighthouse Factory," it boasts the world's largest single-story building in the industry, featuring 31 intelligent electronics motherboard production lines and 36 product assembly lines. Emphasizing automation, digitization, and intelligent innovation, the company places high efficiency as a fundamental aspect of its operational "quality."

-

![2023121509523368]() Challenges

ChallengesAfter the completion of goods scanning, the company's warehouse undergoes full-scale automation. The entire process, from workshop-to-warehouse transportation, automatic receipt of goods by robotic arms, multi-level warehousing of small orders, to the automated packaging, stocking, and delivery of palletized goods, is accomplished without direct human intervention. Achieving an automation rate of 100%, the process yields approximately six times the efficiency of manual labor. This extensive automation involves intricate data flow and collaboration among the Manufacturing Execution System (MES), Warehouse Management Wystem (WMS), and Warehouse Control System (WCS). Faced with growing production complexity, the existing hybrid storage solution falls short of meeting the continuous, efficient, and stable demands of "Finished Goods Warehouse Automation," necessitating a data storage system upgrade.

-

![2023122907162146]() Solution

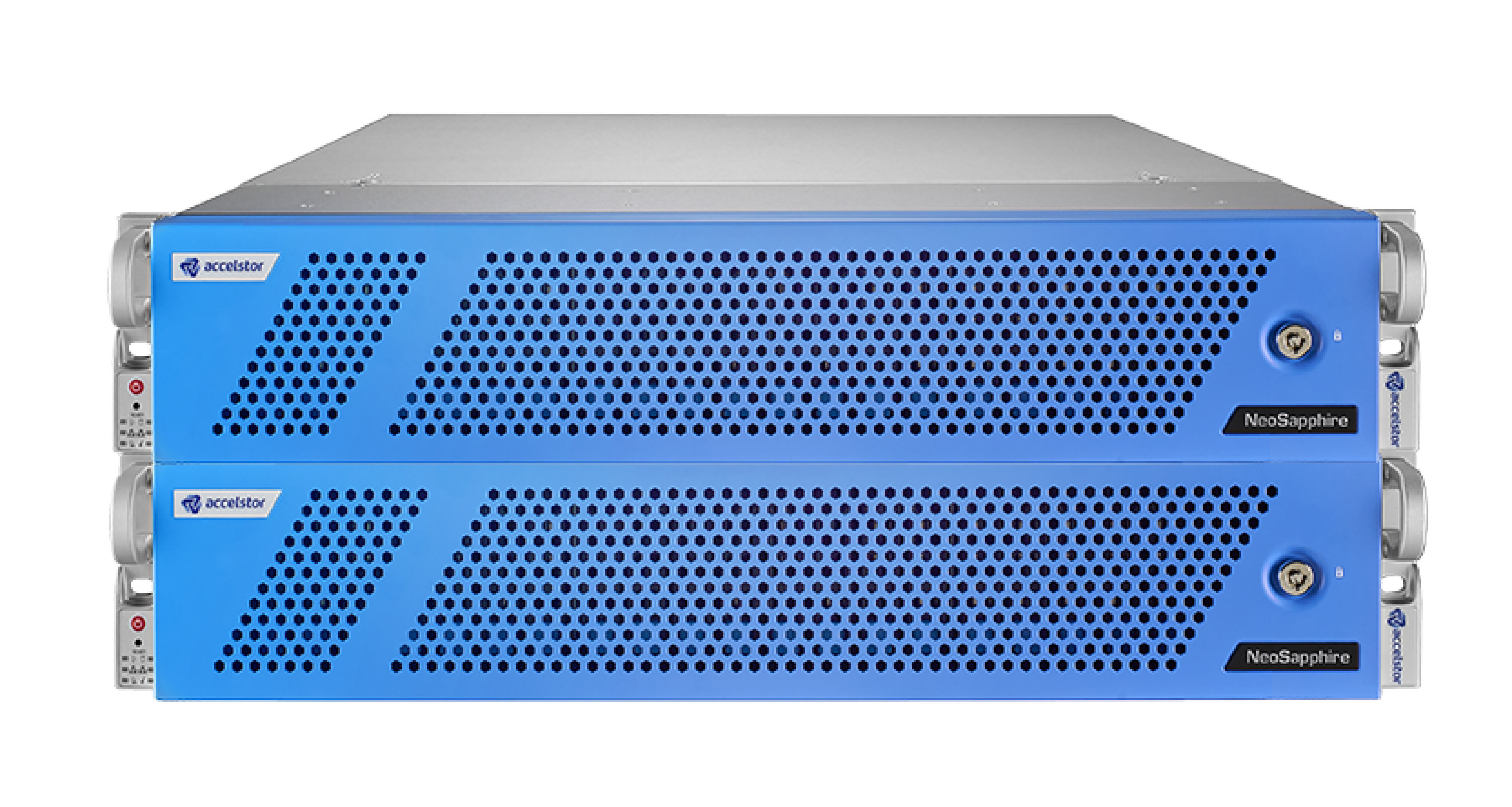

SolutionAfter three months of rigorous performance and disaster recovery testing, AccelStor's NeoSapphire all-flash array, known for its sustained performance, emerged as the ideal choice for the demanding needs of this "Lighthouse Factory."

-

![2023121509523096]() Benefits

Benefits- 5X Improvement in Database Performance: Compared to traditional disk arrays, AccelStor's NeoSapphire all-flash array achieves a remarkable 5X increase in database performance.

- 99.9999% Availability: Featuring the self-developed "non-shared symmetric Active-Active architecture," the data reliability reaches an outstanding 99.9999%, ensuring zero data loss and continuous operations even under extreme failure test scenarios.

- 87.5% Storage Space Savings: AccelStor's innovative DNA aligns seamlessly with the creative background of the "Lighthouse Factory." Post-installation, the all-flash array delivers efficient and stable data storage services for the "Finished Goods Warehouse Automation" project without encountering performance bottlenecks. By activating the data compression function, a compression ratio exceeding 8:1 is achieved. This translates to a data volume of 24TB occupying only 3TB of storage space, opening possibilities for future expansion and additional use case scenarios.